We have professional and experienced engineers who work collaboratively on each project. They will submit detailed manufacturing solutions regarding different components’ characteristics. At each manufacturing stage, our engineers work with the operation team to ensure quality control procedures are properly implemented and the specification is 100% in compliance.

For quality control, we have an excellent inspection team that is built up of rich experienced QC & QA. They will monitor each process of production. Each component or parts will go through our QA for final inspection and testing. Make sure every product is under the customer’s requirement before reaching customers.

Our focus is to close the gap and provide lower-cost manufacturing throughout the world. Sourcing your parts with LBJ is the closest thing to running your own manufacturing facility in China. We offer extreme flexibility for you and your project needs.

xxx

Bespoke automation manufacturers turn out equipment, including molds, dies, machining parts, and cutting tools. LBJ is the best choice for your bespoke automation project

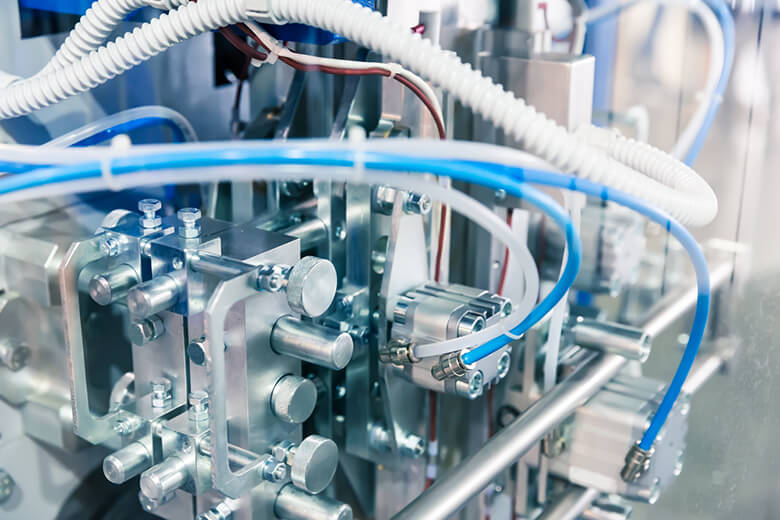

Pressure instruments are applied to measure, monitor, and transmit, liquid, Mass Flow, Air Decay or control pressure. LBJ has experience in precise mechanical parts and effective metal component solutions, which can effectively improve production efficiency, reduce costs, and meet the different needs of pressure-sensing application manufacturers.

LBJ operates a wide range of components that allow precise CNC machining of both standard and custom hydraulic and pneumatic parts. The components for hydraulic & Pneumatic, including Cylinder, valves & Pumps, Pressure Switch, Supercharger, Manifold, Quick disconnect

Motion control is a subfield of automation in which the position or speed of a machine is controlled using some type of device, such as a hydraulic pump, linear actuator, or electric motor. The growth of the motion control market has increased owing to the use of advanced automation equipment, machine tools, advanced medical equipment, sensors, and others.

In the automotive industry, effective quality management is crucial and is regarding every enterprise in the long supply chain. On account of its specificity, the automotive industry is fixing standards of quality for the whole industry. The compliance of every element applied for the production of the car with precisely determined norms and the standard is, in this case, crucial, because the reliability and safety of the ride are conditioning him.

Our preparation work often starts from your purchase order, firstly we will review the purchase order detailed request. Drawing revision is the most important in verifying the process, ensuring the material, dimension tolerances and surface treatment and other technical specifications are the latest before moving to further steps.

Our Engineers will make a flow machining card, and our programmer use 3D software in order to produce a computer model of customer drawings and design. This can help to reveal any potential issues that weren’t evident from the product design itself. We could fastly communicate with our customers and deal with any problems maybe exist.

For a successful custom CNC machining, the critical things necessary to be prepared are the raw materials, Incoming inspection, CNC program, cutting tools, part holding fixtures, and measuring tools. These preliminary procedures will ensure a smooth machining process.

From a fundamental standpoint, the three primary operations in machining are turning, drilling, and milling. Secondary operations can be added to achieve the required shape, precision, mechanical properties, or surface finish. We will machine step by step according to the process flow chat, which could ensure the machining process in the correct way.

The surface finishing process is the final step in CNC machining., the surface treatment is a possible way to obtain sufficient resistance against environmental attack oxidation. It could meet your request for smooth finishes or additional corrosion and wear resistance.

Quality control makes great sense for accuracy and precision. The common metrics checked in machined parts are usually dimensional accuracy, surface finish, and structural integrity.

Packing products as well comply with the packaging standard to avoid the goods being damaged during transportation.

You could choose your safe and convenient delivery ways by (express DHL, UPS Fedex, OCS) or sea transportation

We recently received the CNC parts order from LBJ, and We are incredibly impressed with the quality of the parts. The precision and attention to detail in the machining are exceptional, and the parts fit perfectly with my existing components. I appreciate the high-quality materials used in the manufacturing process, which have resulted in durable and reliable parts. Overall, We are very satisfied with my purchase.

We've ordered CNC parts from several different manufacturers in the past, but I have to say that the parts I received from LBJ machining are by far the most consistent. Every part was identical, with no variation in dimensions or performance. I was particularly impressed with the level of detail and precision that went into the manufacturing process, resulting in parts that fit together perfectly. The consistency of these CNC parts is a testament to the high-quality machining and rigorous quality control processes used by this company. I would definitely order from them again.

I was in need of some very specific and complex parts for a project I was working on, and I wasn't sure if CNC machining would be able to handle the level of customization I required. However, I was pleasantly surprised by the results. The LBJ team at this company was able to take my designs and produce parts that exceeded my expectations. The precision and attention to detail in the machining process were remarkable, and I was particularly impressed by their ability to create parts with intricate geometries and tight tolerances. The capability of CNC machining to complete such complicated customizations is a testament to the skill and expertise of the team at LBJ.

I recently placed an order for CNC machining parts with LBJ, and I was blown away by their professionalism. From the initial quote to the final delivery of the parts, the team was incredibly responsive and communicative. They kept me updated throughout the entire process, providing me with detailed progress reports and answering all of my questions promptly. The quality of the parts was exceptional, with each one meeting my exact specifications. I appreciated the attention to detail and the willingness of the team to go above and beyond to ensure that I was completely satisfied with my order. Overall, I was very impressed with the professionalism of .

Parts can be turned and milled from ferrous or non-ferrous materials to suit customer requirements. The customer’s choice of material depends on the characteristics of the end product, the machining operations required, and the technical suitability of the material for the part to be produced.

We use the following raw materials to produce parts. Please contact us if the material needed for your part is not listed.

Aluminum Alloy, Copper Alloy, Carbon Steel, Stainless Steel, Tool steel, Titanium, and Engineering Plastics.

More money it’s going to cost more if there are greater set-up needs, lengthier cycle times, and additional fixturing or specialized tools.

There are times when a tight fit tolerance is mandatory. However, when carefully considering end-use you can determine between critical and non-critical tolerances, avoid unnecessary tight tolerances, and reduce your cost of quality.