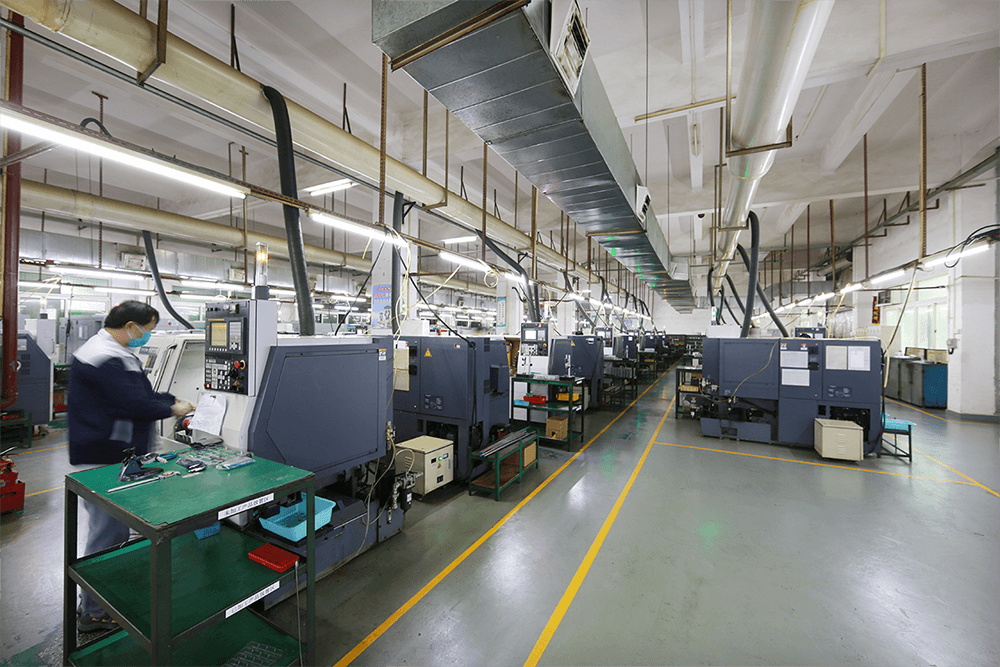

CNC Turning

LBJ’s CNC Turning services deliver incredible machining capacity that enables consistent satisfaction across our clientele.

Our strength in CNC Turning lies in our in-depth knowledge which allows us to provide extremely cost-effective solutions that exceed even the most demanding customer requirements. Such strength is further elevated by our high-speed CNC turning lathes, optimizing a wide array of our precision engineering operations.

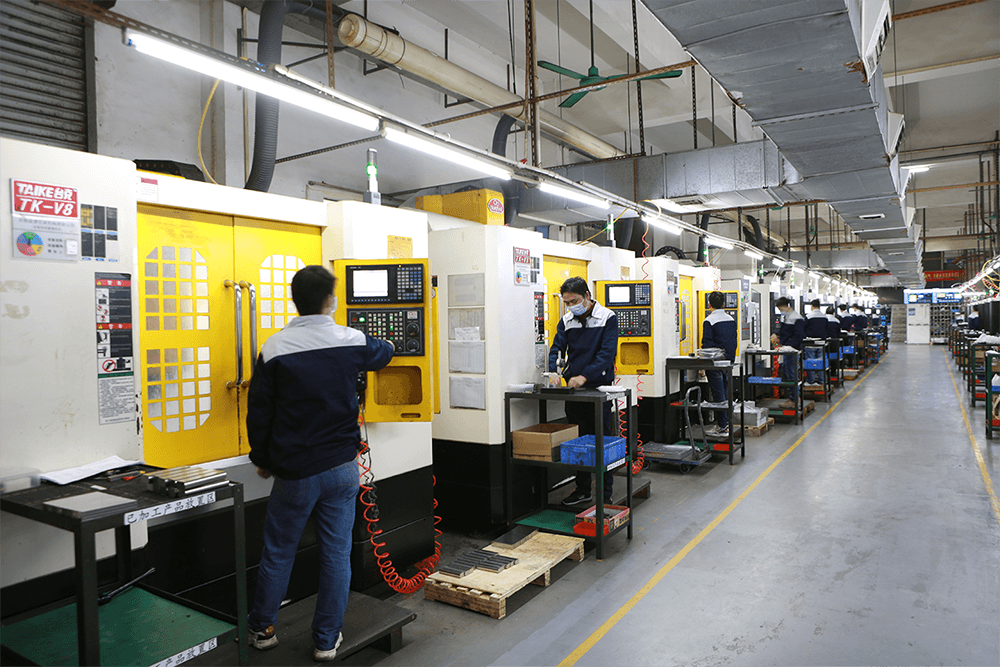

CNC Milling

We offer CNC milling services for any type of custom CNC parts, whether plastics or metals, simple or complex. Our precision 3-, 4-, and 5-axis CNC machines, combined with other advanced capabilities and our experienced team, can provide high-quality CNC machined parts and fast delivery.

We guarantee your CNC milling projects will be handled smoothly by our in-house CNC machining department and supplier network. As a result, you can focus on bringing your product to market. If you need a reliable CNC milling company, LBJ will never let you down!

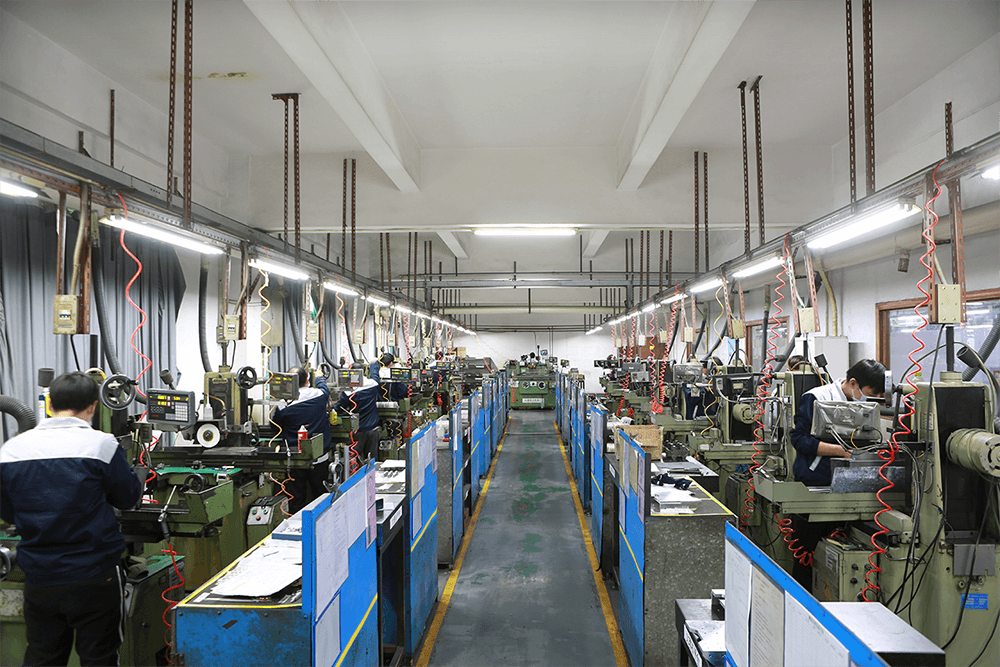

Grinding Service

For the purpose of achieving exceptional finishes and tight OD tolerances, centerless grinding is the usual process after CNC Swiss or CNC Turning of precision machined components.

We offer a full complement of grinding services to satisfy the varied needs of products: In-feed grinding, Through-feed grinding and End-feed grinding, Cylindrical grinding, and Honing. For creating the finest surface finish and micro-hardness, the burnishing process is one of the more advanced finishing techniques we use.

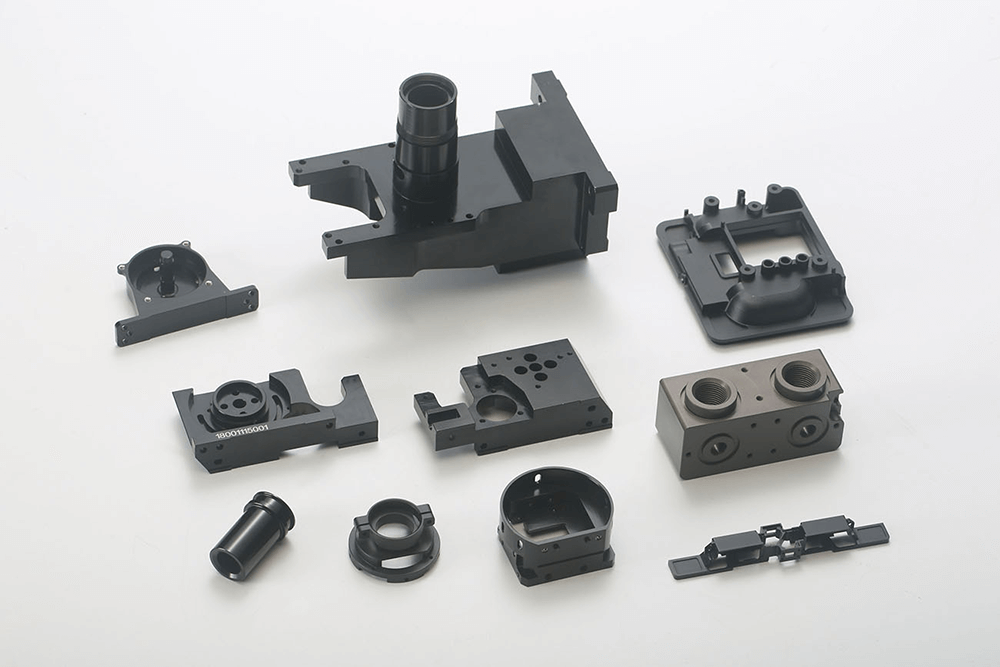

Surface Finish

Surface treatment available: Clear anodize, color anodize, conversion coating, zinc plating, chrome plating, black oxide, paint, and powder coating.

Heat treatment available: Case hardening, carburization, nitridation, quenching, tempering.

Electroplating

We can process the parts using electroplating, which involves applying a thin film of another metal to the metal product. In order to cover the parts, a surface treatment is carried out – cleaning away dirt, degreasing, and washing. After that, the parts are immersed in a special bath, in which galvanic coating is applied.

The galvanic coating offers:- anti-corrosive effect

- increased resistance of the part to wear and friction

- increased temperature resistance

- aesthetic appearance

- electroplating

- galvanization

- oxidation

- chrome plating

- zinc-plating

- gilding and silvering