Industrial Sensors

Pressure sensor: In the field of pressure sensing, CNC-machined products play a crucial role in the production of pressure transducers.

Temperature Sensors: The sensors determine temperature by sensing physical characteristics such as thermal or infrared radiation, substance resistance, or electromagnetic readings. These sensors require high precision in the manufacture of their sensing elements and terminal blocks.

Vibration Sensors: Vibration sensors capture vibration data with the help of sensing components like accelerometers. The most precise accelerometer technology is piezoelectric crystals. CNC machining enables the production of components with consistent dimensional accuracy, ensuring reliable and consistent vibration measurement.

Optical sensors:

Flow Sensors: CNC-machined products play a critical role in the production of flow sensors, such as ultrasonic and magnetic flow sensors. High precision could ensure long-term stable and accurate measuring results.

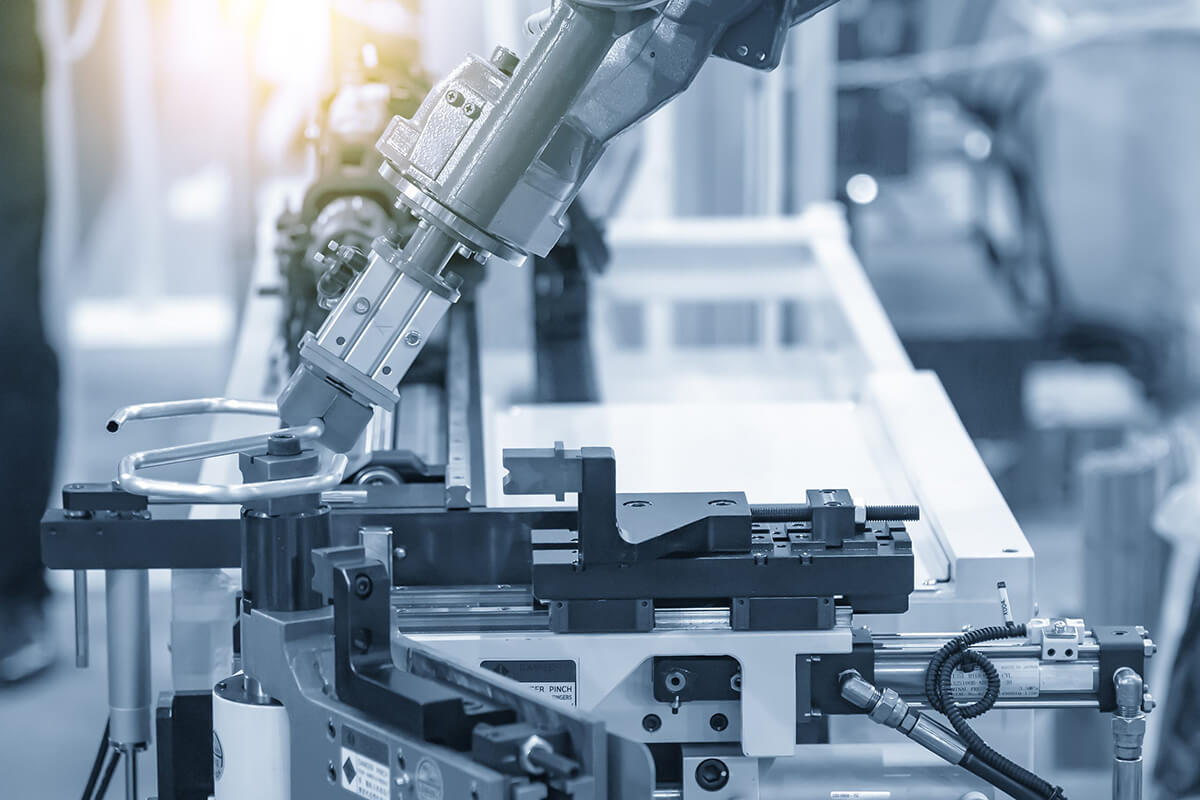

Bespoke Automation

Bespoke automation manufacturers turn out equipment, including molds, dies, machining parts, and cutting tools.LBJ is the best choice for your bespoke automation project

Pressure Instruments

Pressure instruments are applied to measure, monitor, and transmit, liquid, Mass Flow, Air Decay or control pressure. LBJ has experience in precise mechanical parts and effective metal component solutions, which can effectively improve production efficiency, reduce costs, and meet the different needs of pressure-sensing application manufacturers.

Pressure Measurement Technology demands components that meet exact specifications and the highest standards for reliability and quality. There are several benefits of a CNC machine, all of which can be enhanced by ensuring premium quality standards via pressure testing.

With in-depth expertise in fabricating high-precision custom Mechanical and Electrical technology sensing components. Optimum pressure testing of complex CNC parts is crucial to ensure premium-quality standards, satisfy customer needs, and ensure high-performance metrics. On top of that, it is also imperative to minimize production costs if the client does not require high precision.

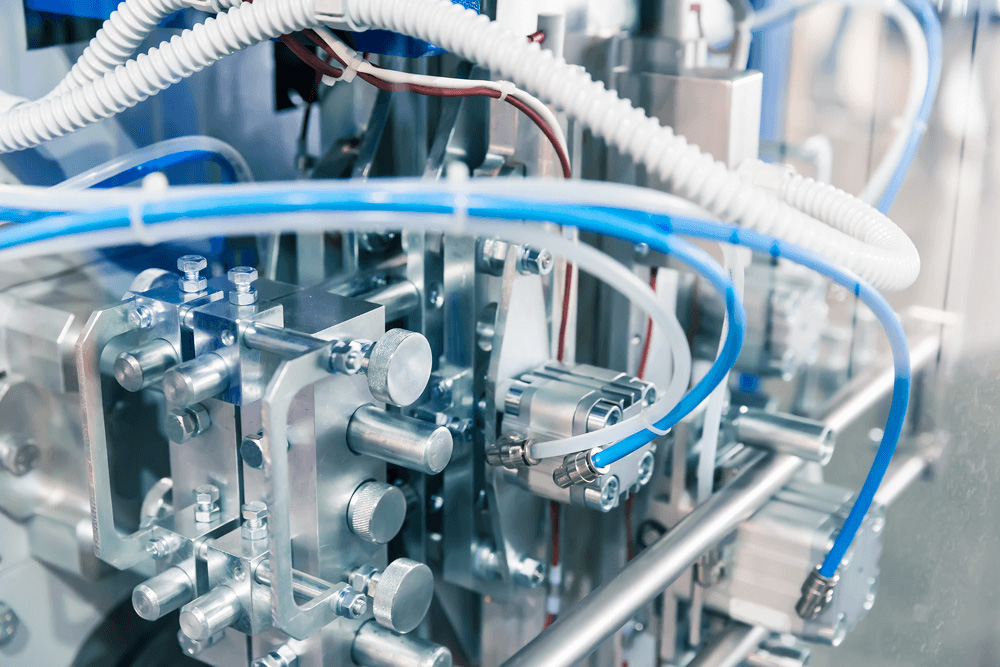

Hydraulic & Pneumatic

LBJ operates a wide range of components that allow precise CNC machining of both standard and custom hydraulic and pneumatic parts. The components for hydraulic & Pneumatic, which including as below cylinder valves & Pumps Pressure Switch supercharger manifold quick disconnect

Motion Controls

Motion control is a subfield of automation in which the position or speed of a machine is controlled using some type of device, such as a hydraulic pump, linear actuator, or electric motor The growth of the motion control market has increased owing to the use of advanced automation equipment, machine tools, advanced medical equipment, sensors, and others. CNC-machined products play a significant role in the production of motion controls. In recent years, the equipment industry has begun to stand out from the traditional industries and carry out in-depth development in the field of motion control application segments.

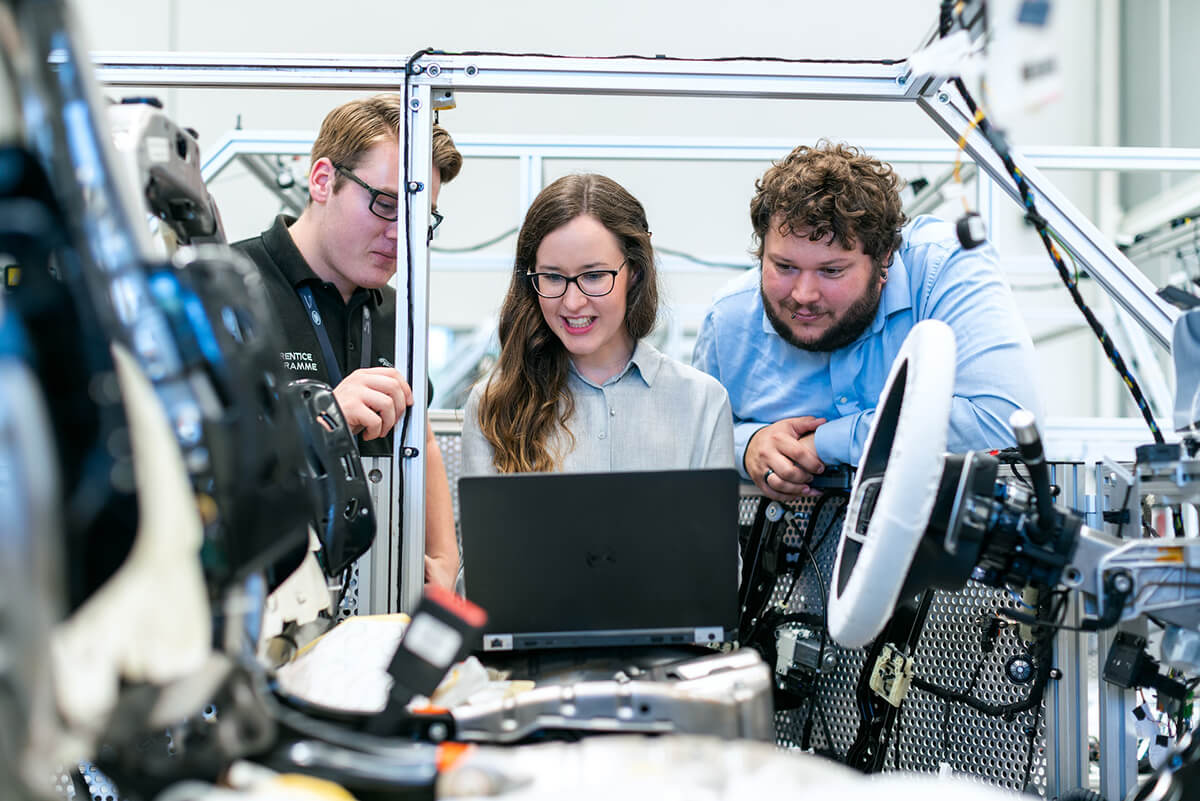

Automotive industry

In the automotive industry, effective quality management is crucial and is regarding every enterprise in the long supply chain.

On account of its specificity, the automotive industry is fixing standards of quality for the whole industry. The compliance of every element applied for the production of the car with precisely determined norms and the standard is, in this case, crucial, because the reliability and safety of the ride are conditioning him.

Produced according to norms increased to the limit and subjected to requiring tests must meet the highest quality requirements. Getting the perfect compliance of the component with precisely determined parameters requires proper managing the processes associated with the quality of the production.

Our ISO 9001:2015 quality systems and extensive knowledge of materials source requirements make LBJ fully compatible with automotive industry expectations. ISO TS16949 certified and IATF since 2015, Our machining processes and equipment ensure quality, control, and performance for the most demanding jobs.